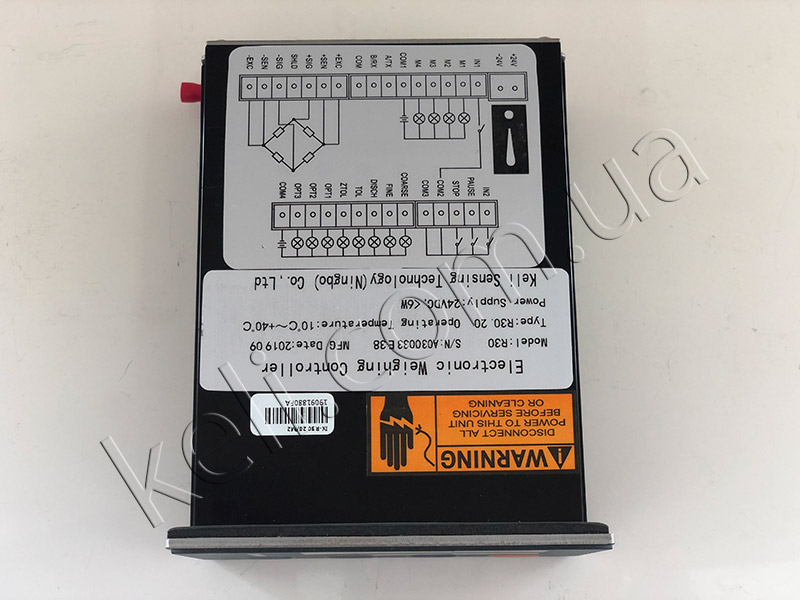

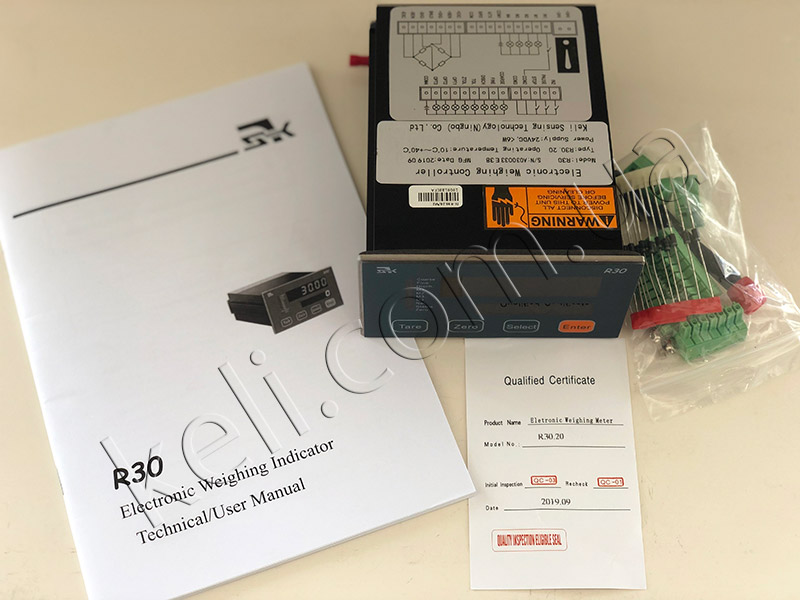

Weighing batching controller R30.20

Controller R30.20 is specially designed for batching of materials and for industrial inspection. Controller is widely applied in packing equipment, in the systems of reservoirs fill-up, in the systems of bulk products batching as well as for batching in different branches of industry, such as metallurgical, chemical, food industries and others.

Main features:

- panel mounting and compact housing;

- possibility of batching in mixed and cyclical mode;

- two speeds of batching;

- independent 4 – component batching;

- 10 recipes saving;

- automatic spillage correction;

- automatic accumulation and analysis of errors;

- 12 relay outputs;

- 4 relay inputs;

- connection standard RS232/RS485;

- support Modbus RTU;

- part manual mode, with mode of combine loading of material;

- in case of emergency shutoff the indicator continues a batching process after restart.

Engineering data

| Analog – digital convertor | Highly accurate, 24 bites, Σ- Δ convertor, Sampling rate 100 Hz |

|---|---|

| Housing | Front panel SS304, IP 65, housing aluminum IP 42 |

| Operating mode | Operating mode 1-4 component batching; cyclic batching, accumulative batching; |

| Number of connecting load cells | Maximum 6 analogue load cells 350Ω |

| Input range | -20mV~20mV |

| Input sensitivity | Over 1,5uV/e |

| Display | Basic: 6 red LED segments and auxiliary: 6 green LED segments. 10 LED status indicators. |

| Serial connection port | Separate port RS- 232/RS- 485 (built-in switcher) |

| Communication protocol | Consistent format, type-out, MODBUS-RTU |

| Relay mode | 4 input. 12 output, maximum load 30 VDC/200 mА. |

| Recipes number | 10 |

| Dimension (height х width х length) | 104х59х130 mm |

| Mounting hole (height х width): | 93 х 46 mm |

| Power supply: | Power supply: 24 V DC, consumption < 30 W |